a. Suitable for welding metal ring and reinforcing plate;

b. Suitable product size:

Carrier plate: width 100mm, length 300mm, thickness 0.8-1.0.

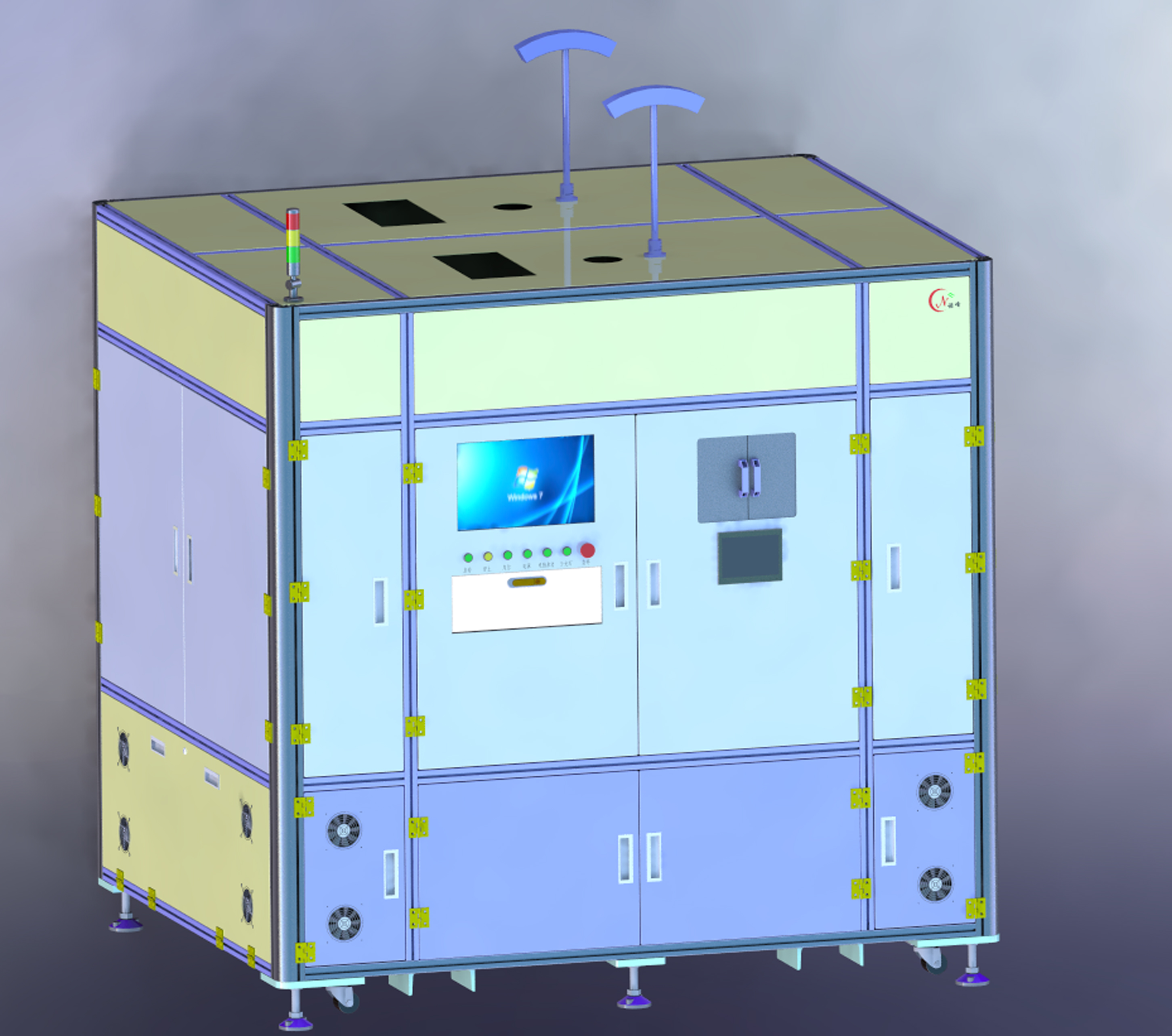

1. The equipment adopts double station flow design; Realize welding on the carrier plate, no need to disassemble the plate, high automation

2. The output mode of the laser is time splitting. With the reasonable design of the mechanical structure, the laser can output light without gaps and maximize the utilization of the laser

3. The welding protective gas is set as coaxial blowing, which can fully protect the product surface; It can also be equipped with side shaft dust collector

4. Welding energy, power, time and defocus can be adjusted; Users can adjust according to actual needs

5. The welding station adopts safety grating and flap sensor with double-layer protection to ensure no laser injury accident due to misoperation

6. Equipped with CCD and optical fiber sensor to ensure the positioning accuracy

7. Equipped with Advantech industrial PC, 19 inch touch display, full Chinese operation surface with user password protection function;

8. The loading and unloading system adopts servo module and air cylinder to automatically position the loading and unloading tray;

9. The stepping motor is used to control the turning of the carrier plate to ensure that the turning angle is accurate and adjustable.

10. The main accessories are imported to effectively ensure the stability of the equipment;

11. The parameters are input and saved by the touch display to facilitate debugging. The equipment has sound and light alarm function.